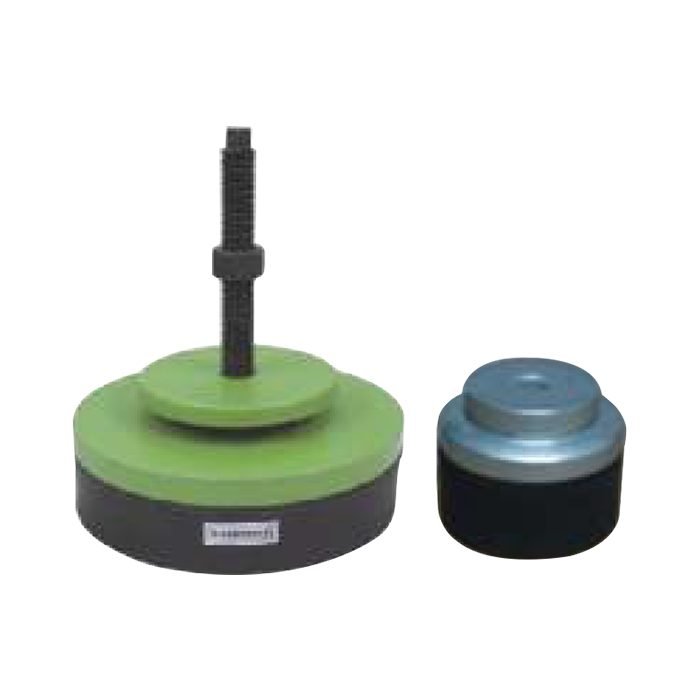

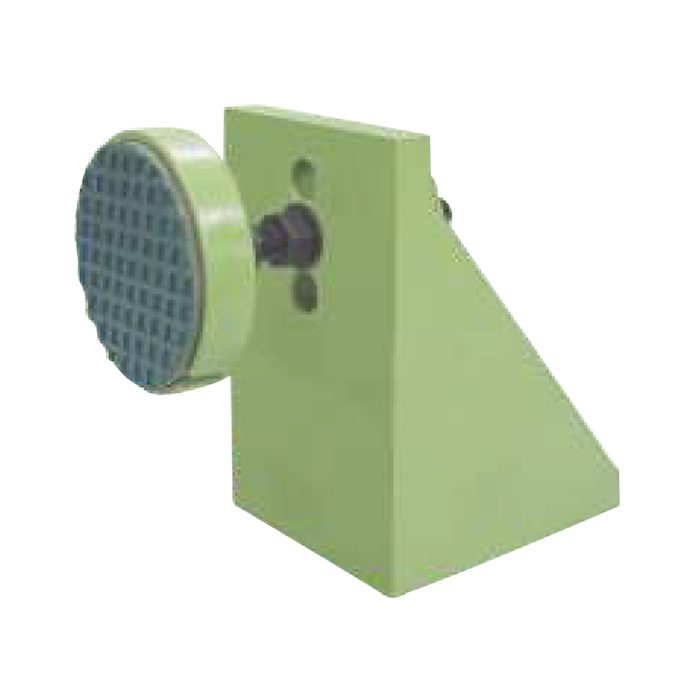

TPM Series Mounts are designed for industrial machines that require the machines to be placed at a height of 100mm / 150mm for proper cleaning and repairing under the machine as per IMTMA guidelines. Series DBP mounts are designed for machines which require precision leveling along with vibration reduction and are desired to be firmly mounted with the isolator or machines with high axial thrust and do require any anchoring to the floor.

These mounts provide 2 holes on the top plate of the wedge. The bolt which is supplied as a standard accessory with these wedge mounts can be fixed in any of these two holes. While installing the machine, the bolt can be fixed in the hole which makes sure that most of the wedge mount is covered by the leg/base of the machine.

| Model | Load (Kg/pc) | Length (L) (mm) | Width (B) (mm) | Height (H) at mean position (mm) | d (mm) | e (mm) | Bolt size | Adjustment range (mm) | Applications |

| DBP1-u | 1100 | 115 | 115 | 100 / 150 | 50 | 24 | M16 | 8 | Tool Room Machine, Plastic Injection Moulding Machines, Pressure Die Casting Machines, Shaper, Printing and Textile machines etc. |

| DBP2-u | 1800 | 150 | 150 | 100 / 150 | 60 | 23 | M18 | 10 | |

| DBP3-u | 3200 | 200 | 200 | 100 / 150 | 75 | 27 | M20 | 12 | |

| DBP4-u | 4000 | 200 | 250 | 100 / 150 | 95 | 27 | M20 | 18 | |

| DBP5-u | 6400 | 250 | 320 | 100 / 150 | 125 | 55 | M24 | 18 | |

| DBP6-u | 9600 | 300 | 400 | 100 / 150 | 148 | 50 | M24 | 20 | |

| DBP1-m | 1400 | 115 | 115 | 100 / 150 | 50 | 24 | M16 | 8 | Lathe Machines, Machining Centers, Milling Machines, Precision Grinding Machines, Drilling Machines, Turning Centers, Transfer Lines etc. |

| DBP2-m | 2200 | 150 | 150 | 100 / 150 | 60 | 23 | M18 | 10 | |

| DBP3-m | 4000 | 200 | 200 | 100 / 150 | 75 | 27 | M20 | 12 | |

| DBP4-m | 5000 | 200 | 250 | 100 / 150 | 95 | 27 | M20 | 18 | |

| DBP5-m | 8000 | 250 | 320 | 100 / 150 | 125 | 55 | M24 | 18 | |

| DBP6-m | 12000 | 300 | 400 | 100 / 150 | 148 | 50 | M24 | 20 | |

| DBP1-i | 1800 | 115 | 115 | 100 / 150 | 50 | 24 | M16 | 8 | Power Presses, Stamping Machines, Shearing Machines, Punching Machines, For Machines with high vertical impact |

| DBP2-i | 2900 | 150 | 150 | 100 / 150 | 60 | 23 | M18 | 10 | |

| DBP3-i | 5200 | 200 | 200 | 100 / 150 | 75 | 27 | M20 | 12 | |

| DBP4-i | 6500 | 200 | 250 | 100 / 150 | 95 | 27 | M20 | 18 | |

| DBP5-i | 10000 | 250 | 320 | 100 / 150 | 125 | 55 | M24 | 18 | |

| DBP6-i | 15000 | 300 | 400 | 100 / 150 | 148 | 50 | M24 | 20 | |

| DBP1-s2 | 950 | 115 | 115 | 100 / 150 | 50 | 24 | M16 | 8 | Medium Presses, Punching Presses, Centerless Grinding Machines, Gear Shapers, High Speed Machines on upper floors |

| DBP2-s2 | 1600 | 150 | 150 | 100 / 150 | 60 | 23 | M18 | 10 | |

| DBP3-s2 | 2800 | 200 | 200 | 100 / 150 | 75 | 27 | M20 | 12 | |

| DBP4-s2 | 3500 | 200 | 250 | 100 / 150 | 95 | 27 | M20 | 18 | |

| DBP5-s2 | 5500 | 250 | 320 | 100 / 150 | 125 | 55 | M24 | 18 | |

| DBP6-s2 | 8500 | 300 | 400 | 100 / 150 | 148 | 50 | M24 | 20 | |

| DBP1-s1 | 600 | 115 | 115 | 100 / 150 | 50 | 24 | M16 | 8 | Tools Room Machines on suspended Floors, Light Weight Presses, Compressors etc. |

| DBP2-s1 | 1000 | 150 | 150 | 100 / 150 | 60 | 23 | M18 | 10 | |

| DBP3-s1 | 1800 | 200 | 200 | 100 / 150 | 75 | 27 | M20 | 12 | |

| DBP4-s1 | 2200 | 200 | 250 | 100 / 150 | 95 | 27 | M20 | 18 | |

| DBP5-s1 | 3500 | 250 | 320 | 100 / 150 | 125 | 55 | M24 | 18 | |

| DBP6-s1 | 5200 | 300 | 400 | 100 / 150 | 148 | 50 | M24 | 20 |