Fabrication shops are continuously pressured with demands for better delivery, improved quality and tighter tolerances. And the press brakes have evolved into a versatile and imperative tool for fabrication shops for both specialized sheet metal work and continuous production applications .The marriage of CNC to the machine has pushed its usefulness even further. .

A Press Brake is a machine used primarily to punch, form, and/or bend metal. But by their very nature, press brakes will generate vibratory shocks and vibrations that not only affect the performance of the metal working process but also transmit and disturb other machinery and office structures located in the premises.

Dynemech vibration isolation mounts ensure faster production with minimum initial installation costs and control vibrations hence, improving die and machine life. Also, it needs to be noted that vibration isolation of machinery to prevent the transmission of vibration and noise has become one of the pre requisites to modern workshop building and layout planning. Light weight construction and the need to install mechanical equipment on upper floors, adjacent to quiet areas makes it imperative to control vibration. Furthermore, rising space rentals many a times, necessitates developing testing and quality control labs nearby sheet metal fabrication shop floor. Thus to ensure productive profitability from our machinery we must focus on vibration damping.

Dynemech has successfully installed many press brakes on wedge mounts to ensure flexible installation, improved machinery performance, excellent vibration damping along with precision alignment and levelling. High coefficient of friction of assembled insulation plates prevent “machine walking” to adhere to OSHA criteria for machinery installation. Our anti vibration pads are ROHS-compliant and are exported to many countries around the world.

Fig 1: Press Brake installed on Vibro Mounts

Dynemech Press Brake Foundation Mounts with Elastomeric Pads offer many benefits:

1. Increased machinery working life.

2. Installation Savings – Machines are installed faster and easier.

3. Simplified machine installation.

4. Precision Levelling and alignment of machine mounts reduces machine wear and tear & increases tool life

5. Machine “walking” prevented.

6. Different products/customized solutions available.

7. Reduced shock and vibration.

8. Simple integration into the production plant due to flexible installation.

9. Better Structural Safety.

Dynemech is the leading manufacturer/exporter of Precision Levelling Machine Mounts for all kinds of Industrial machines. Dynemech’s engineering team provides complete guidance in proper mount selection for various different types of machines depending on the machine specifications and external factors (like installation location). They provide detailed installation notes with illustrative diagrams for correct precision machine mounts installation.

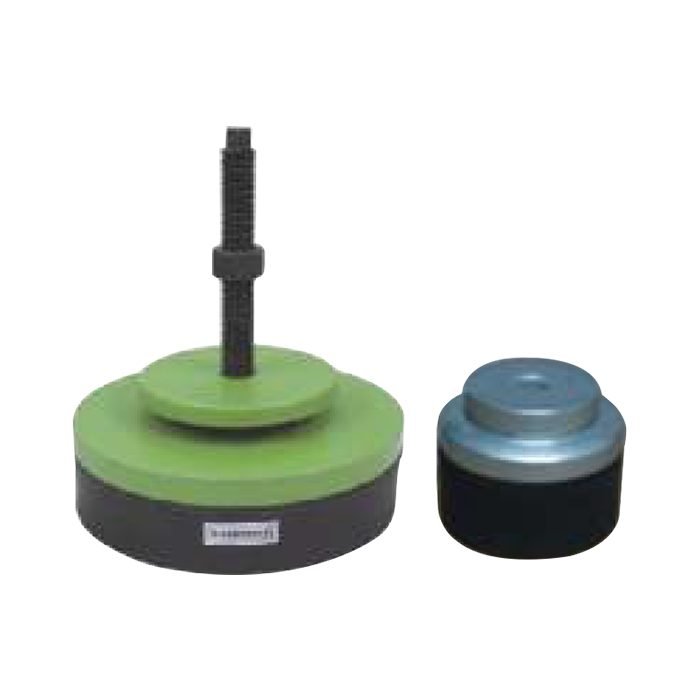

Press-Brake Installation Spring Isolator Mounts

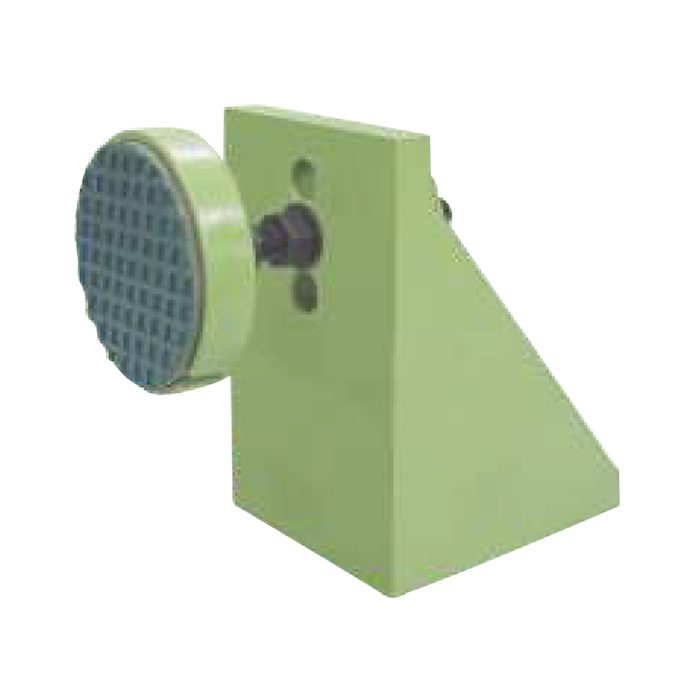

Press-Brake-Mounted Wedge-Mounts

Precision Levelling and Vibration Damping in Press-Brakes.

Press-Brake Installation Spring Mounts

Press-Brake-Mounted Wedge-Mounts

Installation of Heavy Press Brake Machines.