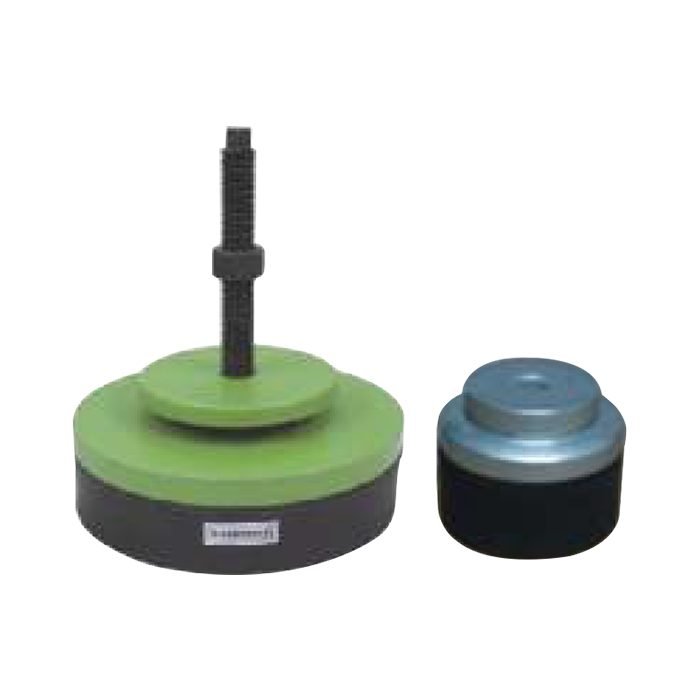

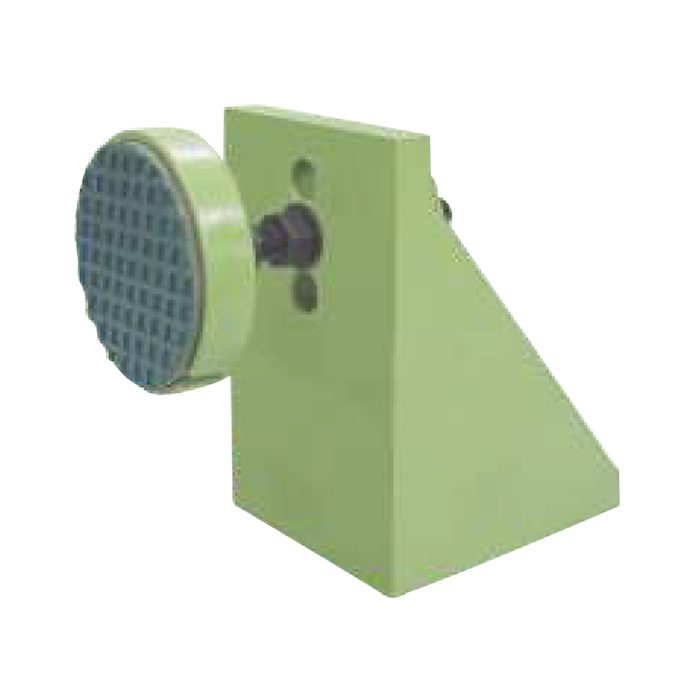

A complete Dynemech DLPM system consists of three master pneumatic isolators for 3-point precision leveling. Each pneumatic damping isolator consists of a leveling valve which is the load sensing and height controlling element. Systems are supplied with automatic height control valves, tubing and all other pneumatic accessories necessary for complete system installation.

Dynemech DLPM Mounts have minimal setting time. Long setting time using pneumatic isolators is not acceptable because precision measuring and positioning machines can suffer repeatability errors and through put losses.

Isolation Characteristics

Natural Frequency for the Pneumatic Isolator

Vertical – 2.5 – 2.7 Hz

Horizontal – 2.0 – 4.5 Hz

Damping

Vertical (Adj.) – 6% – 20%

Horizontal – 5% – 6%

Leveling Accuracy of +/- 0.15 mm over 1 meter is available.

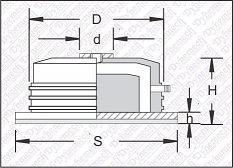

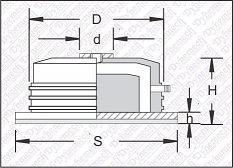

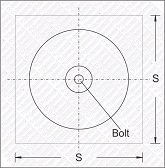

| Model | Load (Kg/pc) | Max. Pressure Bar | S mm | D mm | H App. mm | d mm | h mm | Bolt |

| DRAS1 | 25 – 60 | 3 | 88 | 84 | 64 | 41 | 6 | M10 |

| DRAS2 | 80 – 300 | 5 | 125 | 120 | 70 | 80 | 6 | M12 |

| DRAS3 | 270 – 800 | 6 | 182 | 174 | 88 | 100 | 6 | M16 |

| DRAS4 | 650 – 1500 | 6 | 252 | 250 | 108 | 127 | 8 | M16 |

| DRAS5 | 1200 – 3400 | 6 | 370 | 360 | 111 | 200 | 8 | M20 |

| DRAS6 | 3000 – 6500 | 6 | 500 | 480 | 114 | 315 | 8 | M20 |

Applications: Active insulation of high speed power presses, textile machines, vibration test rigs, engine test beds, blowers etc and passive insulation of measuring & testing machines / equipments, high precision grinding / polishing machine, surface plates, spectrometers, roughness tester, hardness tester etc.