A machine press, commonly shortened to press, is a machine tool that changes the shape of a work-piece. Press working may be defined as chip less manufacturing process by which various components are made from sheet metal. This process is also called cold stamping. These process are generally carried out at room temperature. In cutting operations the work piece is stressed beyond its ultimate strength. the stress caused in metal by applied forces will be shearing stresses e.g.- blanking, piercing, trimming, shaving. Forming operations- the stresses are below the ultimate strength of metal. In these operation there is no cutting forces but only contour of work piece is changed to get the desired product. Drawing is operation of producing cylindrical or box shaped components with straight or tapered edges. In drawing the area of developed blank before drawing should be same as the surface area of metal in drawing.

All these operations on the press produce very large impact forces. These forces travel through the press frame into the foundation. The foundation produces a rebound force equal to the impact force and this travels inside the machine. These internal forces are produced by the stamping operation on a press when the press is bolted to a foundation or installed on isolators. However, the magnitude of the vibration within the press is lower when using vibration isolators. Bolting the press rigidly to a foundation subjects it to more vibration and impact force. Vibration isolators are cushions that transform a sudden shock pulse into a decaying series of longer duration forces. Imagine the force of hitting a wall with our fist. Now hitting the wall with the same energy, but with our hand in a boxing glove. It is obvious that the later hurt less! This is because the impact duration is longer, effectively reducing the impact force. Short duration impacts mean higher force.

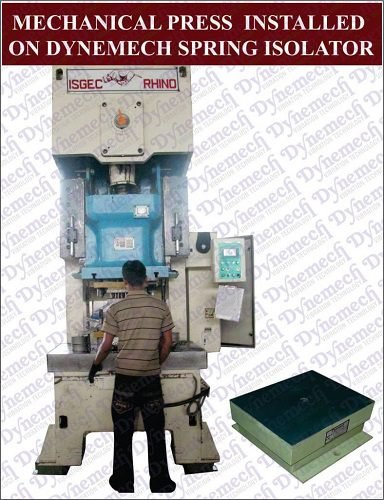

This same thing happens on a press rigidly bolted to the foundation. The sudden release of potential energy at impact causes the press foot to slam against the foundation. This fast duration, high magnitude force hits the foundation and the foundation responds in kind, sending damaging forces back into the press. In case the press is isolated from the foundation with Dynemech passive vibration isolators, the isolators will absorb most of the impact energy of the blow. Now, the impact force at the foundation is reduced and also the rebound force transmitted by the foundation into the press machine.

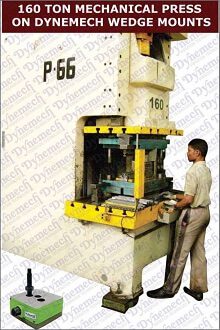

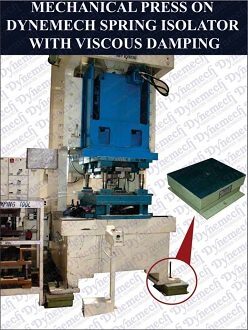

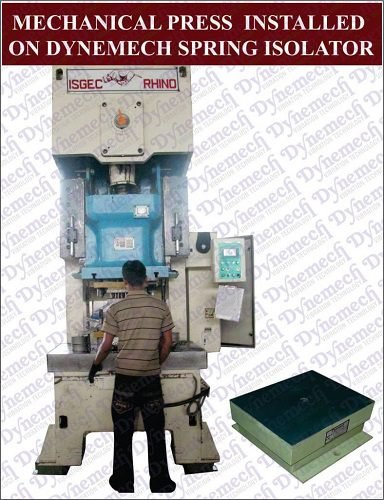

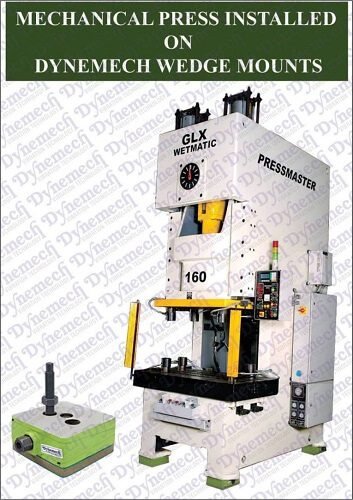

Fig 1: Power Presses on Dynemech Spring Isolators & Wedge Mounts

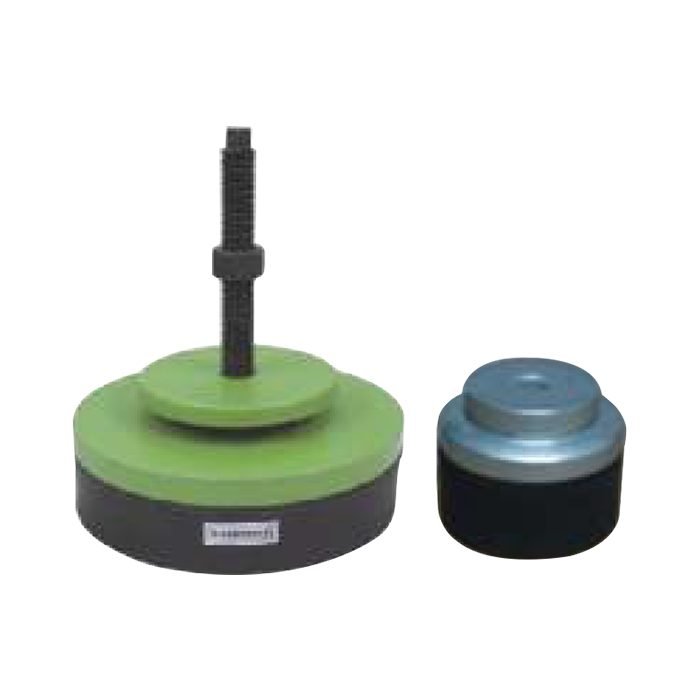

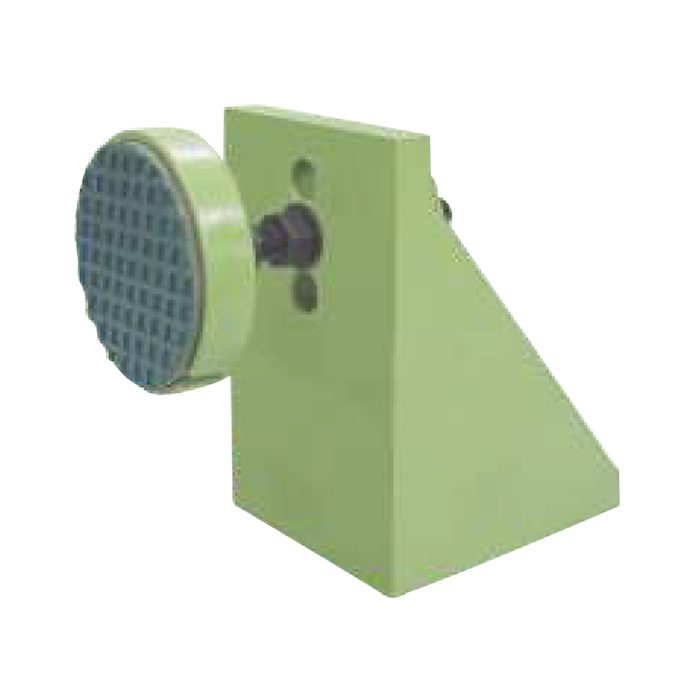

Dynemech Spring Isolators with viscous damping / Wedge Mounts with Elastomeric Pads offer many benefits:

- Installation Savings – Machines are installed faster and easier.

- Precision Levelling and alignment features of Dynemech Wedge Mounts reduces machine wear and tear; increases tool life; and increases productivity by reducing downtime and improving part quality and repeatability.

- Reduce vibration and shock levels for a better work environment.

- Different products/customized solutions available.

- Simple integration into the production plant due to flexible installation.

- Machine can be easily re-located and Re-Levelling is much faster and easier.

- Significantly increased productivity without higher breakdown risk.

- Better Structural Safety.

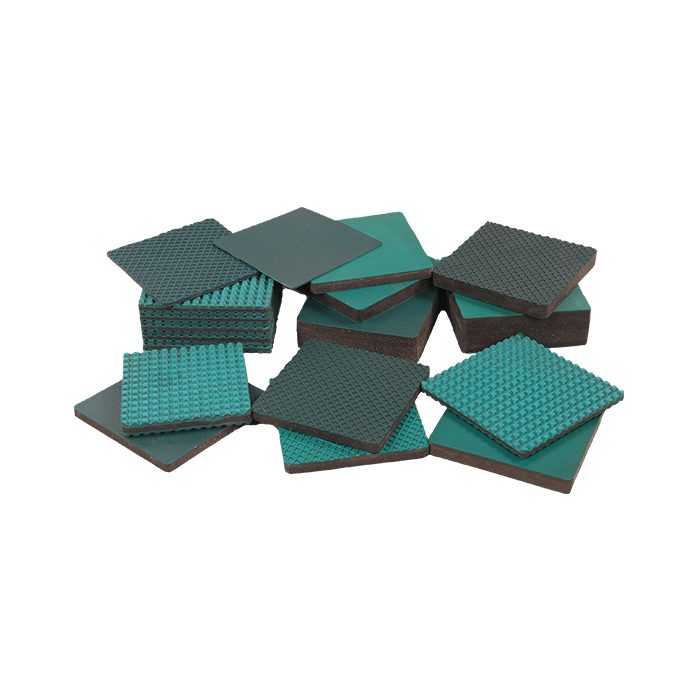

Dynemech Anti Vibration Mounts suitable for Power Presses

With increasing production speeds of high speed presses, vibration problems are amplified. Vibrations not only put at risk the productivity and the operation time, but also the machinery and parts life is greatly reduced.

Dynemech is the leading manufacturer/exporter of Anti-Vibration Mounts to all kinds of Heavy Press machine OEM manufacturers in India and abroad. Dynemech’s engineering team provides complete guidance in proper pad selection for various different types of press machines depending on the machine specifications and external factors (like installation location). They provide detailed installation notes with illustrative diagrams for correct anti-vibration pad installation.